HOW TO USE

Volumetric water meter is used for measuring

water flow rate through pipe, with the characteristics of long-term clear

readings. water meter includes impeller, impeller box, case, movement and meter

glass. Volumetric

rotary-piston principle of measurement ensures registration even at the very

lowest rates of flow with maintained accuracy over the flow range. Can be installed

in horizontal, vertical, without affecting accuracy.

FUNCTIONS

1. Rotary piston water meter is volumetric

water meter, using the principle of piston rotation.

2. High

accuracy: the counter is separated from the water.

3. Adopt

high-quality materials: stable and reliable performance.

4. Install

in the pipeline with good water quality.

5. Inlet are

equipped with non-return valve to prevent backflow.

TECHNICAL PARAMETERS

|

Nominal Diameter

|

Class LEVEL

|

Over Flow Q4

|

Common Flow Q3

|

Demarcation Flow Q2

|

Min Flow Q1

|

Min Reading

|

Max Reading

|

|

mm

|

m3/h

|

1/h

|

m3

|

|

15

|

C

|

3.125

|

2.5

|

25

|

15.625

|

0.00005

|

9999

|

|

20

|

C

|

5

|

4

|

40

|

25

|

0.00005

|

9999

|

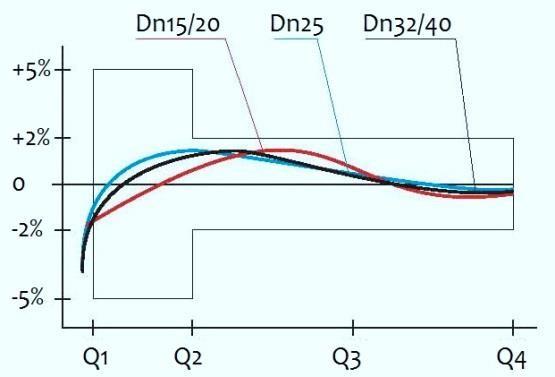

Max. Permission Error (for T30):

From Q1 inclusive up to but excluding Q2 is ± 5%;

From Q2 inclusive up to and including Q4 is ± 2%;

INSTALLATION

1. The installation of water meter should meet

the installation requirements of GB/T778.2

2. The

caliber of water meter shall be based on the size of the pipeline and the usual

used water flow is no more than common flow of the water meter; and the

installation location shall be avoided insolation, flooding, freezing and

pollution, and convenient for installation, removing and reading data.

3. The sands and stones and other sundries in the

pipeline, such as hemp thread shall be cleaned firstly in case of water meter

breakdown.

4.

Volumetric water meter can be installed in horizontal and vertical

5. Please leave enough space for repairing, and

installation according to water flow direction on the pipe.

6. Please do

not apply too much force when connecting the rotary liquid sealed water meter

and pipe, to avoid damaging the meter body and leakage.

7. If the

water meter is installed on the inlet of the boiler, shall install check valve

on the outlet of water to prevent the return current of hot water and steam

from damaging the water meter.

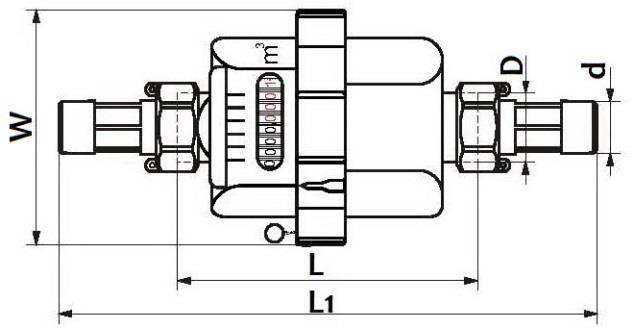

DIMENSION

|

Size

|

Dn15

|

Dn20

|

Dn25

|

Dn32

|

Dn40

|

|

L

|

115

|

130

|

170/260

|

260

|

300

|

|

L1

|

209

|

234

|

290/380

|

384

|

431

|

|

D

|

G3/4B

|

G3/4B

|

G1-1/4B

|

G1-1/2B

|

G2B

|

|

d

|

R1/2

|

R3/4

|

R1

|

R1-1/4

|

R1-1/2

|

|

W

|

90

|

96

|

112

|

139

|

174

|

MAIN TECHNIQUES

1. Piston adopts high

quality material to ensure stable and durable performance

2.

Liquid-sealed register ensure long-term clear reading

3. Ensures high sensitivity and accurate

registration throughout a wide flow range

4. Mechanical

transmission movement equates to maximum reliability

5. Corrosion

resistant body

PRODUCTS

PRODUCTS