PRODUCTS

PRODUCTSNB-IoT ultrasonic water meter is used for measuring water flow rate in the pipe. which send meter data to server via wireless NB-IoT network.

HOW TO USE

NB-IoT ultrasonic water meter is used for measuring water flow rate through pipe via wireless NB-IoT network upload water consumption

The whole NB-IoT ultrasonic meter reading system consists of ultrasonic water meter, and monitoring management software. The management center can read and monitor water meter accumulated water consumption, instantaneous water flowrate info by NB-IoT network directly.

NB-IoT water meter can configure 3 days to upload for each month, and in these three days, each day can set 2 time periods to bring device online, and the user can configure time according to the need. During online time, management center can read real-time accumulated water consumption

FUNCTIONS

Timed upload

The ultrasonic water meter defaults to upload data at 0:00 every day, and the timing upload start time can be set as needed.

Reading real-time and historical data

When the ultrasonic water meter is online, we can use the management software to read real-time accumulated water consumption and other data information, or read freeze accumulated water consumption of each day for last two months and monthly water consumption for last 24 months.

Parameter setting

Related parameters of ultrasonic water meter can be set by setting relevant preset commands on the software.For example, we can set the reporting frequency, the starting time of intensive collection, the alarm threshold of large flow, the number of retry reports, and the configuration parameters of water meter.

Remote valve control(with valve control meter)

Valve opening and closing commands can be sent to the ultrasonic water meter through the management software. After receive the valve closing command and the meter LCD will display OFF Close (indicating that the valve is closed). Valve opening command is sent to the ultrasonic water meter, after receive the command meter LCD will display ON after the smart water meter receives the command (indicating that the valve is opened).

Ultrasonic Water Meter(no valve) Ultrasonic Water Meter(with valve)

TECHNICAL PARAMETERS

Caliber(DN)

15mm

20 mm

25mm

Overload Flow Rate

(Q4)

3.125 m3/h

5 m3/h

7.875 m3/h

Common Flow Rate (Q3)

2.5 m3/h

4 m3/h

6.3 m3/h

Transitional Flow

Rate (Q2)

0.025 m3/h

0.040 m3/h

0.063 m3/h

Minimum Flow Rate (Q1)

0.0156 m3/h

0.025 m3/h

0.0394 m3/h

Measurement Range

(Q3/Q1)

160, 250

Working Pressure Range

0.03~1.6MPa

Level of Pressure Loss

Δp63

Flow Profile

Sensitivity Level

U10,D5

Working Temperature

T30 (water temperature

0.1 ℃~ 30 ℃)

Environment Safe Class

B

EMC Level

E1

IP Degree

IP68

Accuracy Level

Class 2

Button

Photosensitive button

LCD Display

8 digits with prompt

Minimum Reading

Normal working status

Meter inspection

status

0.001m3

0.00001m3

Working Status Indicator

Ordinary display: forward

cumulative flow, reverse cumulative flow, instantaneous flow, signal strength

Display after press

button: Meter ID, time, IMEI code, CCID code, water temperature, version

number

Communication Method

NB communication;

infrared communication

Communication

Frequency

B3:1800Mhz B8:900MHz B20:800MHz B5:850Mhz

Relative Humidity

5%~100%

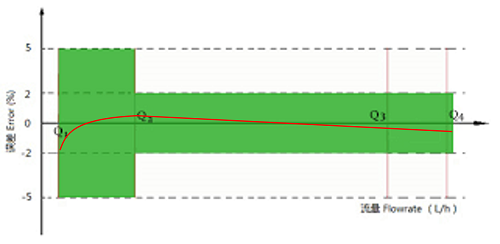

Maximum Allowable

Error

Q1≤Q<Q2 Error≤±5%;Q2≤Q≤Q4 Error≤±2%

Working Current

Without valve control:

≤ 30µA (static current); ≤

60µA (current during

communication)

With valve control: ≤ 10µA (static current); ≤ 60µA (current during communication)

Battery

3.6V disposable

lithium batteries

Material of Base Meter

Brass

INSTALLATION

Preparation work before installation

1. Ultrasonic NB-IoT water meter adopts NB-IoT network for communication. A signal mark of

2. Login the smart meter integrated management system (SMIMS) server and enter the management system on a computer that is connected to internet.

3. Create a file for the water meter with its ex-factory number. For details, please refer to the ID number and IMEI number on the water meter.

4. After pressing the button on the ultrasonic water meter, the screen will start displaying. The information of meter ID, time, IMEI, temperature can be seen.

5. The ultrasonic water meter can be installed in area which is covered by NB-IoT network. The signal value can be checked by the management software and it is not recommended to

install the meter in where the signal value is below 5.

Attention

1. Water meter installation should be complied with GB/T778.2 installation requirements.

2. It is suggested to install the filter in front of the ultrasonic water meter and install the valve in front of the filters to facilitate the maintenance and cleaning of the filters.

3. Wash the pipe before installation to avoid threads, tones or other sundries in the pipeline from causing malfunction of the meter.

4. Ultrasonic water meter should be installed horizontally (display face up).

5. Please leave enough space for repairing, and install according to water flow direction on the pipe.

6. Please do not apply too much force when connecting the ultrasonic water meter and pipe, to avoid damaging the meter body and causing water leakage.

7. Please do not knock the meter shell violently or cause strong vibration during installation, in case of damaging the equipment.

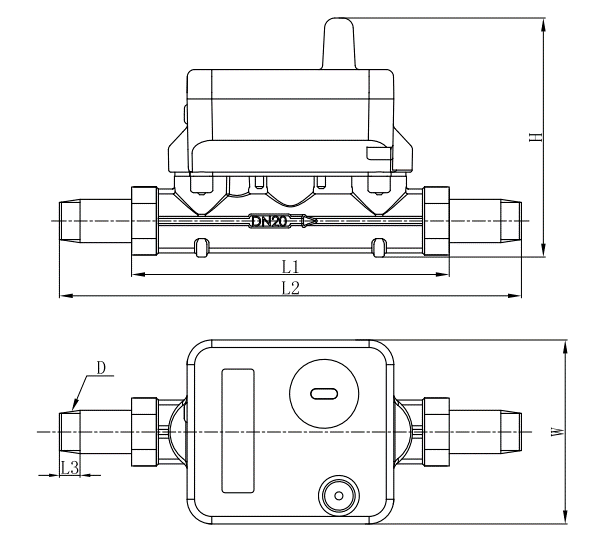

DIMENSION

Dimensions of water meter without valve control

Caliber

L1(mm)

L2(mm)

L3(mm)

H(mm)

W(mm)

D(mm)

DN15

130

220

14

120

95

R1/2

DN20

130

230

16

120

95

R3/4

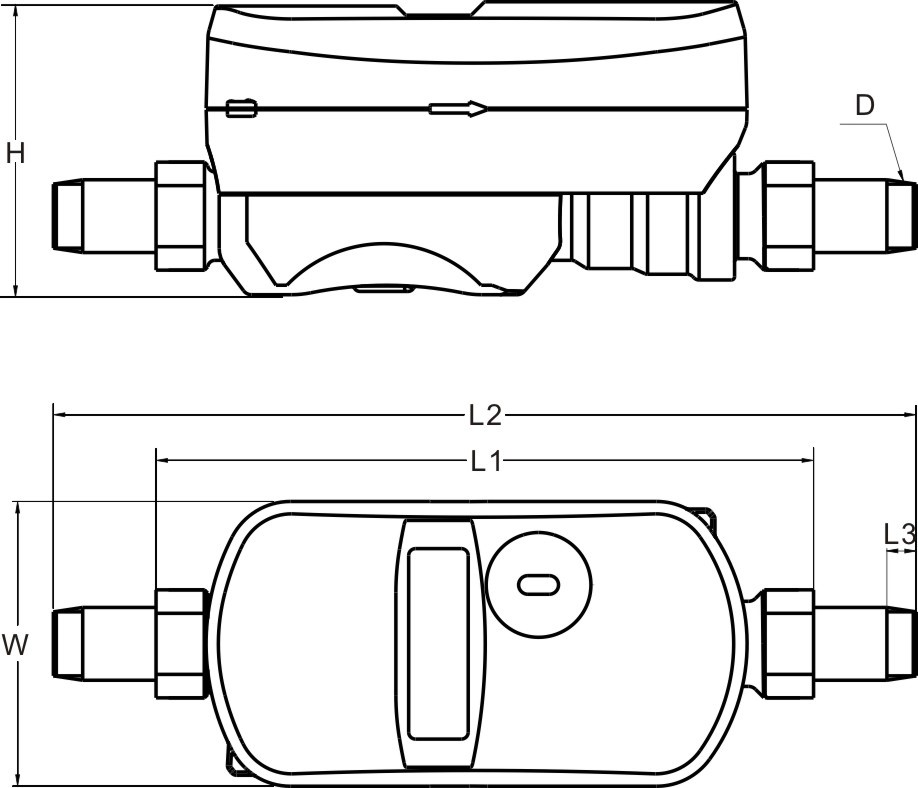

Dimensions of water meter with valve control

Caliber

L1(mm)

L2(mm)

L3(mm)

H(mm)

W(mm)

D(mm)

DN20

195

295

16

89.5

87

R3/4

NOTE:

L1---Length of the ultrasonic water meter

L2---Length of the ultrasonic water meter and the joints

L3---Effective length of the threaded connection

H---Height of the ultrasonic water meter

W---Width of the ultrasonic water meter

D---Nipple joint

MAIN TECHNIQUES

1. NB-IoT technique, signal network in-depth coverage (work normally in underground and piping well), ultra-low power consumption, stable and reliable communication.

2. Infrared communication function, handheld unit enables data querying and setting.

3. Micro-power technology, timed detection technology, NB-IoT ultrasonic water meter quiescent current is not greater than 15μA.

4. Integrated structure of base meter and electronic part. Totally sealed design: all the circuits are sealed by high performance casting glue, no exposed electrode, applicable in moist environment.

5. Automatic data correction technology. It adopts the new type CPU, and real-time data saving to avoid data loss when power off.

7. LCD display is with high definition and wide temperature range.

8. Flow is segmented calibration with high accuracy

9. Measuring mechanism has no moving parts and no wear and tear forever. The measuring accuracy will not be influenced by using time.

10. Convenient installation. Both vertical and horizontal are ok.

11. The water meter supports forward and reverse flow metering.

12. There is an empty tube anhydrous indicator and a signal quality indicator on the LCD display.

13. Valve timing technique

14. Automatic valve position detection technique

E-mail:export@suntront.com

E-mail:export@suntront.com