HOW TO USE

The 4G large caliber ultrasonic water meter adopts the advanced ultrasonic measurement technique to measure the water flow in pipes, and upload water meter data by 4G way.

The whole 4G meter reading system consists of wireless ultrasonic water meter, 4G modem, and monitoring management software. The management center can read and monitor water meter accumulated water consumption, instantaneous water flowrate info by 4G network directly.

The FS smart water meter upload data info through 4G to management center, such as accumulated consumption curve, real time accumulated consumption, instantaneous flow etc. Besides, the water meter also can detect the pipe pressure. It will collect the pipe pressure data to management center at fixed time. The administrator could check the data through software, if there is abnormal, the alarming message will be uploaded to management center. The management center can transmit alarming message to administrator for them check and resolve in time.

FUNCTIONS

1. Measured by ultrasonic, and separately adjusted, with high precision,

and avoid magnet attack.

2. There is no moving parts,

and no wear and tear, and maintain 100% accuracy for its lifetime.

3. The real time monitor period can be set by software, at monitor

period, the software can communicate with the terminal and read or freeze the terminal

data.

4. The data can be freeze each 15 minutes, and one message can read 96

freeze data each day, which save a lot of meter reading cost.

5. 4G is the priority, which save meter reading cost.

TECHNICAL PARAMETERS

|

Caliber

|

Overload Flowrate

(Q4)

|

Permanent

Flowrate

(Q3)

|

Transitional

Flowrate

(Q2)

|

Minimum

Flowrate

(Q1)

|

|

20

|

5 m³/h

|

4 m³/h

|

0.08

m³/h

|

0.05

m³/h

|

|

25

|

7.875

m³/h

|

6.3

m³/h

|

0.126

m³/h

|

0.0788

m³/h

|

|

40

|

20

m³/h

|

16

m³/h

|

0.32

m³/h

|

0.20

m³/h

|

|

50

|

31.25

m³/h

|

25

m³/h

|

0.5

m³/h

|

0.3125

m³/h

|

|

65

|

50

m³/h

|

40

m³/h

|

0.8

m³/h

|

0.5

m³/h

|

|

80

|

78.75

m³/h

|

63

m³/h

|

1.26

m³/h

|

0.7875

m³/h

|

|

100

|

125

m³/h

|

100

m³/h

|

2 m³/h

|

1.25

m³/h

|

|

125

|

200

m³/h

|

160

m³/h

|

3.2

m³/h

|

2 m³/h

|

|

150

|

312.5

m³/h

|

250

m³/h

|

5 m³/h

|

3.125

m³/h

|

|

200

|

500

m³/h

|

400

m³/h

|

8 m³/h

|

5 m³/h

|

|

250

|

787.5

m³/h

|

630

m³/h

|

12.6

m³/h

|

7.875

m³/h

|

|

300

|

1250

m³/h

|

1000

m³/h

|

20

m³/h

|

12.5

m³/h

|

|

400

|

2000

m³/h

|

1600

m³/h

|

32

m³/h

|

20

m³/h

|

|

Maximum Allowed

Error

|

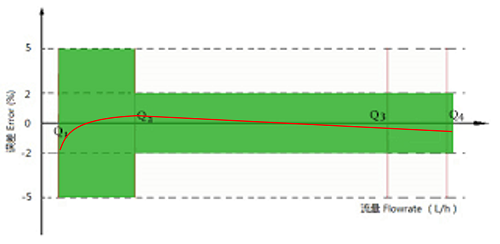

Q1≤Q<Q2 Error≤±5%;

Q2≤Q≤Q4 Error≤±2%

|

|

Minimum Display

of Flowrate

|

0.01m3 (using

status)

0.00001m3 (checking

status)

|

|

Digits of

LCD

|

8 digits

|

|

Max Accumulated

Flowrate

|

4.2×109 m3(Only

final 8 numbers can be displayed when accumulated flow rate is more

than 99999999m3 )

|

|

Working Status

Indicator

|

LCD display

in turn

|

|

Working Temperature

|

0.1℃~30℃;

|

|

Pressure Resisting

|

1.6MPa

|

|

Loss

of Pressure

|

Δp25

|

|

Flow Section

Sensitivity Level

|

U10,D5

|

|

Climate & Mechanical

Environment Safety Level

|

Class

B

|

|

EMC level

|

E1

|

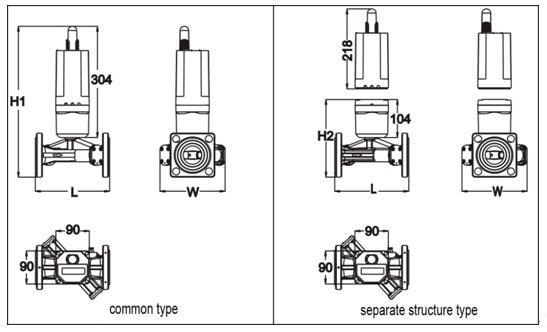

INSTALLATION

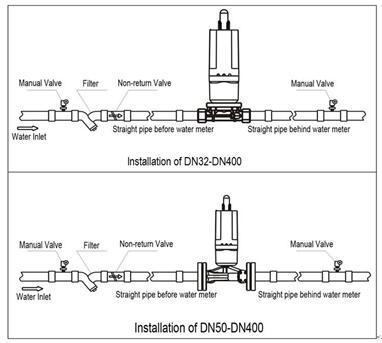

1) Installation of common type water meter:

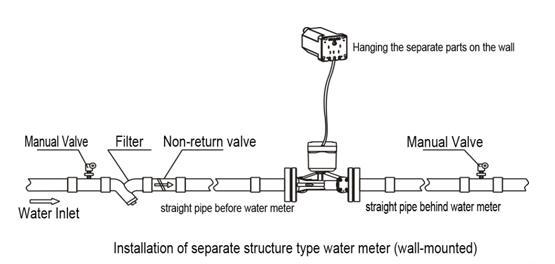

2) Installation of separate structure type water meter:

Note:

Common type water meter is recommended to install above the ground, and

separate structure type water meter adopts underground installation (mounted

close to the entrance of the well or directly install on the well cover).

3) Notice:

1. The installation of water meter should meet the installation requirement of GB/T 778.2

2. It is suggested that install a filter in front of the water meter and install valve in front of the filter, convenient for repairing and cleaning the filter.

3. Before installation, please clean the pipe firstly to avoid small stones or other sundries inside the pipe, which will cause problem for water meter.

4. During the installation,

please don’t wrench, move or knock the component inside of the pipe, to avoid

knocking against the meter body.

5. Please leave enough space for repairing, and installation according

to water flow direction on the pipe.

6. Please do not apply too

much force when connecting the water meter and pipe, to avoid damaging the

meter body and result in water leakage.

7. Please do not knock meter

shell violently or cause sharp pounding, avoid breaking the water meter.

8. When install the separate structure type water meter, the cable

between two parts is 3 meters.

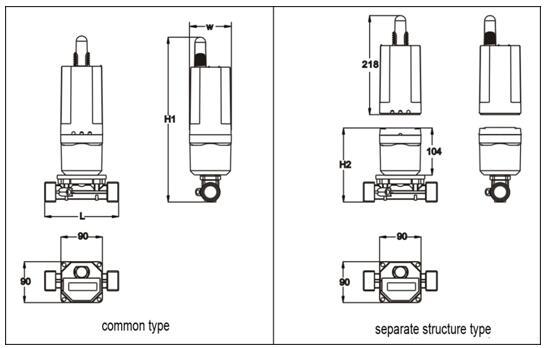

DIMENSION

1) Dimension of DN32-DN40

2) Dimension

of DN50~DN300

|

Caliber(mm )

|

Length

L(mm )

|

Width

(mm )

|

Height

H1(mm )

|

Height

H2(mm )

|

Connection Way

(¢E-n×¢D)

|

|

DN32

|

180

|

90

|

336

|

136

|

Screw G1-1/2B

|

|

DN40

|

200

|

90

|

349

|

149

|

Screw G2B

|

|

DN50

|

200

|

140

|

432

|

232

|

Flange¢125-4×¢18

|

|

DN65

|

200

|

160

|

454

|

254

|

Flange¢145-4×¢18

|

|

DN80

|

225

|

185

|

467

|

267

|

Flange¢160-8×¢18

|

|

DN100

|

250

|

200

|

490

|

290

|

Flange¢180-8×¢18

|

|

DN125

|

250

|

250

|

469

|

269

|

Flange¢210-8×¢18

|

|

DN150

|

300

|

285

|

499

|

299

|

Flange¢240-8×¢22

|

|

DN200

|

350

|

340

|

554

|

354

|

Flange¢295-12×¢22

|

|

DN250

|

450

|

405

|

639

|

439

|

Flange¢355-12×¢26

|

|

DN300

|

500

|

460

|

694

|

494

|

Flange¢410-12×¢26

|

MAIN TECHNIQUES

1. Totally seal design, waterproof, moisture proof, anti-attack and against broken.

2. Easy for installation, can be installed horizontally or vertically.

3. Smart water meter with remote valve control: there is no wire connection between smart water meter and valve controller, easy for installation.

PRODUCTS

PRODUCTS