PRODUCTS

PRODUCTSPrepaid IC card large caliber ultrasonic water meter is separate structure, which adopts a contactless IC card to store water volume and monitor water consumption.monitor water consumption.

HOW TO USE

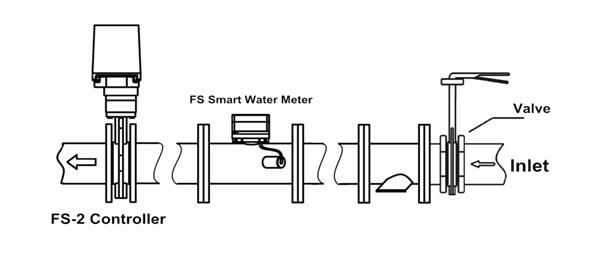

Prepaid IC card large caliber ultrasonic water meter is separate structure, composed by FS smart water meter and FS-2 controller.

The controller can be installed in a convenient place with wireless connection to facilitate user to manage their consumption more easily.

The FS-2 controller built-in microcomputer, customers purchase water volume at vending points and upload water volume by swiping his IC card on the induction area of the controller. FS smart water meter adopts advanced ultrasonic measuring technology, used for measuring water flow passing through pipelines and regularly upload total water consumption wirelessly to controller, which will subtract the used water volume accordingly. When water volume is used up, controller will close valve to stop water supply.

There is an optional function of setting for daily limited water volume. If finished daily limited water volume, water meter will close valve whatever whether there is water remains in the controller.

FS-2 controller will open valve automatically on the next day to supply same daily limited water volume again.

FUNCTIONS

1. Prepaid function. User can open valve and get water supply after swipe the purchased card on the controller.

2. Infrared communication function. The meter’s data can be set by hand-held unit.

3. Wireless data interactive function. The meter and the controller can be interchange data at multi time interval, to make sure the meter info’s reliability and timeliness.

4. Historical data storage function. It can store latest 18 month of water consumption, which is convenient for user’s inquiry and statistic.

5. Historical record inquiry function. Swipe the IC card on serial number of the meter, you can check the current time, this month water consumption and latest 18 month of record.

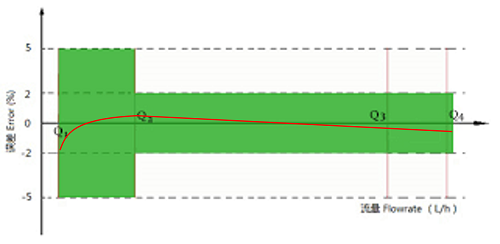

TECHNICAL PARAMETER

|

Caliber (DN) |

Minimum Flowrate (Q1) |

Transitional Flowrate (Q2) |

Permanent Flowrate (Q3) |

Overload Flowrate (Q4) |

|

32 |

0.125 m³/h |

0.20 m³/h |

10.0 m³/h |

12.5 m³/h |

|

40 |

0.20 m³/h |

0.32 m³/h |

16.0 m³/h |

20.0 m³/h |

|

50 |

0.625 m³/h |

1.00 m³/h |

25.0 m³/h |

31.25 m³/h |

|

65 |

1.00 m³/h |

1.60 m³/h |

40.0 m³/h |

50.0 m³/h |

|

80 |

1.575 m³/h |

2.52 m³/h |

63.0 m³/h |

78.75 m³/h |

|

100 |

2.50 m³/h |

4.00 m³/h |

100 m³/h |

125 m³/h |

|

125 |

4.00 m³/h |

6.40 m³/h |

160 m³/h |

200 m³/h |

|

150 |

6.25 m³/h |

10.0 m³/h |

250 m³/h |

312.5 m³/h |

|

200 |

10.0 m³/h |

16.0 m³/h |

400 m³/h |

500 m³/h |

|

250 |

15.75 m³/h |

25.2 m³/h |

630 m³/h |

787.5 m³/h |

|

300 |

25 m³/h |

40.0 m³/h |

1000 m³/h |

1250 m³/h |

|

Static Working Current |

< 10uA |

|||

|

LCD Digits |

8 digits |

|||

|

Max Accumulative Flow |

4.2×109 m³(when>999999.99 m³, it only display last 8 valid digit) |

|||

|

Working Pressure |

1.6MPa |

|||

|

Loss of pressure |

△p25 |

|||

|

Installation Way |

Horizontal or vertical |

|||

|

Flow Section Sensitivity Level |

U10,D5 |

|||

|

Climate & Mechanical Environment Safety Level |

Grade B |

|||

|

EMC |

E1 |

|||

INSTALLATION

The FS smart water meter and FS-2 controller are installed on the pipe and the meter shall be in front of the controller. The meter connects with the controller wirelessly without cable connection.

The meter address has been set before leave factory, and if there is no another water meters within 100 meters, then no need to set. If there are other meters nearby, then need to set the water meter by PDA. (Details are on PDA instruction.)

It is strongly suggested install them separately and keep distance between them.

It is strongly suggested set this before installation.

We use smart meter without sensor as an example, the instruction are as follows:

Note:

1) It is suggested that install a filter in front of the water meter.

2) It is suggested that install valve in front of the filter, convenient for repairing and cleaning the filter.

3) Before installation, please clean the pipe firstly to avoid small stones or other sundries inside the pipe.

4) During the installation, please don’t wrench, move or knock the component inside of the pipe, to avoid knock against the meter body.

5) Please leave enough space for repairing, and installing according to flow rate direction on the pipe.

6) FS water meter can be installed horizontally or vertically on the water inlet. When installed horizontally, two pieces of energy converter must be in the same horizontal plane. When installed vertically, it must be installed on the straight pipe with the water flow direction from down to up.

7) Don’t use excessive force when connects the water meter with pipe to avoid crushing the sealed washer and water leaking.

8) Take care on delivery and avoid storage at strong magnetic field.

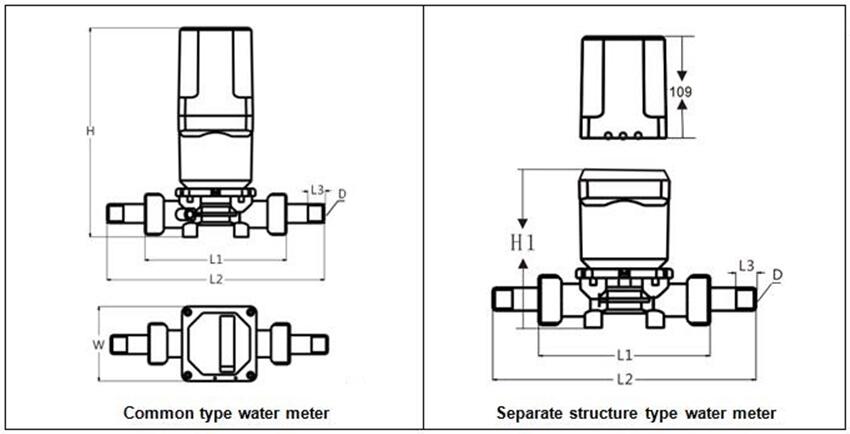

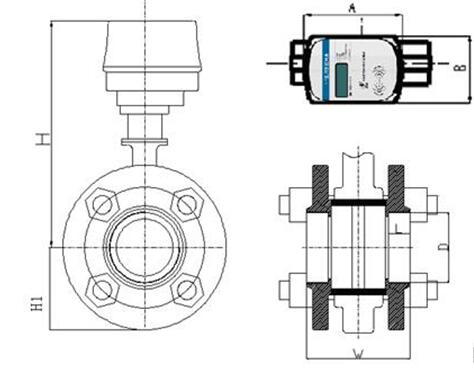

DIMENSION

1) Dimension of FS water meter (DN40)

|

DN (mm) |

L1 |

L2 |

L3 |

H |

H1 |

W |

D |

|

40 |

200 |

324 |

25 |

304 |

206 |

90 |

R1-1/2 |

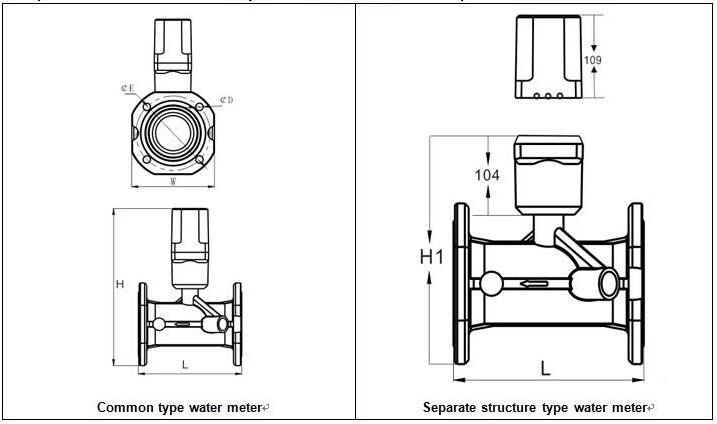

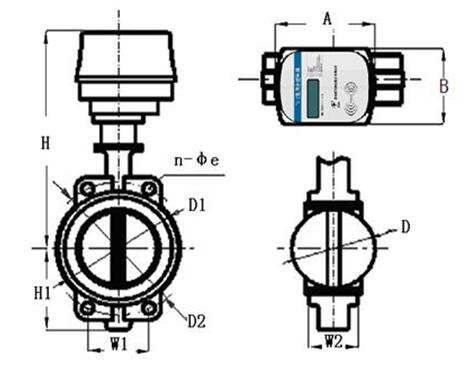

2) Dimension of FS water meter (DN50~DN300)

|

Caliber (DN) |

Length L (mm) |

Width W (mm) |

Height W (mm) |

Connection method ¢E-n×¢D |

|

50 |

200 |

150 |

200 |

Flange ¢125-4×¢18 |

|

65 |

200 |

170 |

205 |

Flange ¢145-4×¢18 |

|

80 |

225 |

195 |

240 |

Flange ¢160-8×¢18 |

|

100 |

250 |

220 |

255 |

Flange ¢180-8×¢18 |

|

125 |

250 |

230 |

285 |

Flange ¢210-8×¢18 |

|

150 |

300 |

270 |

310 |

Flange ¢240-8×¢22 |

|

200 |

350 |

320 |

350 |

Flange ¢295-8×¢22 |

|

Flange ¢295-12×¢22 |

||||

|

250 |

450 |

405 |

450 |

Flange ¢355-12×¢26 |

|

300 |

500 |

460 |

500 |

Flange ¢410-12×¢26 |

3) Dimension of controller DN40

DN

A

B

H1

H

D

W

L

40

130

161

73

320

11/2

100

20

4) Dimension of controller DN50-DN300

DN

A

B

H1

H

D

D1

D2

W1

W2

n

e

50

130

161

80

350

52.9

100

120

85

42

4

23

65

130

161

89

370

64.5

110

136

96

45

4

27

80

130

161

95

376

78.8

121

160

61

45

8

18

100

130

161

114

395

104

156

185

71

52

4

25

125

130

161

127

415

123

176

215

82

54.5

4

23

150

130

161

139

425

155

212

238

91

56

4

25

200

130

161

175

435

202

259

295

113

61

4

25

250

130

161

203

467

250.5

325

357

92.4

65

4

29

300

130

161

242

572

301.6

403

407

105.3

77

4

29

MAIN TECHNIQUES

1) Alarms when voltage is low.

2) Automatic data correction technology.

3) LCD display, with high definition and wide temperature range.

4) Flow rate has 8 levels and are separately adjusted, with high precision.

5) Ultra-low energy consumption (static power consumption is less than 7uA).

6) The tube adopts forging technology.

7) Measuring mechanism has no moving parts and no wear and tear forever. Maintain 100% accuracy for its lifetime.

8) There is optic electric interface, adopt infrared tool can read meter.

9) Pre-alarm tech of flow sensor: when the communication is unmoral or destroyed maliciously, the controller can recognize it and close valve automatically to avoid waste of water.

E-mail:export@suntront.com

E-mail:export@suntront.com