HOW TO USE

The FS-Z M-BUS water meter system consists of M-BUS water meter, collector, concentrator and management software.

1. Bottom layer communication: M-BUS collector and measurement meter transmit data by M-BUS line with 4 channels, and can connect the meter according to any topological structure. Build in backup battery, could works for 48 hours normally, and the data can be saved for 10 years if power is cut off.

2. Middle layer communication: Middle layer communication means the communication between the concentrator and collector. This communication is by wireless RF way, no need of communication line. The wireless communication distance between the

concentrator and collector can be about 3km at wide open area.

3. Upper layer communication: Communication methods indicate below can be selected between concentrator and management center.

(a) GPRS Communication Mode

(b)Telephone Line Communication Mode

(c) RS232 Communication Mode

(d) Ethernet Communication Mode

FUNCTIONS

1.Totally sealed design, waterproof.

2. Automatically memorize the wheel code position and no need initiation.

3.

Avoid external strong magnetic attacking, high performance of

anti-interference.

4. Effectively solve the phenomenon

of reversing and hammering.

5.

Adopt M-BUS communication interface, with long distance transmission.

6. No need power supply for daily work.

7. With remote valve control function that can stop water supply remotely.

TECHNICAL PARAMETERS

|

Caliber(DN)

|

15mm

|

20mm

|

25mm

|

|

Overload Flowrate (Q4)

|

3.125 m³/h

|

5 m³/h

|

7.875 m³/h

|

|

Permanent Flowrate (Q3)

|

2.5 m³/h

|

4 m³/h

|

6.3 m³/h

|

|

Transitional Flowrate

(Q2)

|

0.05 m³ /h

|

0.08 m³/h

|

0.126 m³/h

|

|

Minimum Flowrate (Q1)

|

0.0313 m³/h

|

0.05 m³/h

|

0.0788 m³/h

|

|

Measurement Range

(Q3/Q1)

|

80

|

|

Minimum Reading

|

0.0001m³

|

|

Maximum Reading

|

9999m³

|

|

Measure Unit

|

1m³

|

|

Working Temperature

|

0.1℃~30℃(cold water)

0.1℃~90℃(hot water)

|

|

Communication Interface

|

M-BUS

|

|

Pressure Level

|

△P63

|

|

Working Pressure

|

0.03MPa~1MPa

|

|

Flow Section Sensitivity

Level

|

U10, D5

|

|

Climate and Mechanical

Environment Safety Level

|

B

|

|

EMC

|

E1

|

INSTALLATION

1) Before install the water meters, please read and record the meter’s address and match it with the user. The meter address is a printed number on the meter. For example, the printed number on the meter is “101011293058”, and

then the meter address is “101011293058”.

2) The installation of water meter

shall meet with the installation requirement of GB/T778.2.

3)The

caliber of water meter shall be based on the size of the pipeline and the usual

used water flow is no more than common flow of the water meter; and the

installation location shall be avoided insolation, flooding, freezing and

pollution, and convenient for installation, removing and reading data.

4)

The water meter shall be installed horizontally (display surface is upward).

5)

The sands and stones and other sundries in the pipelines shall be cleared.

6)

The arrow on the water meter should be the same as the water flow in the

pipeline.

7)

If the water meter is installed on the inlet of the boiler, shall install check

valve on the outlet of water to prevent the return current of hot water and

steam from damaging the water meter.

8)

It shouldn’t use too much force when connect the water meter and pipeline, in

case of damaging the water meter. First, put the joint into the union nut,

then, reverse the connector nut to install the water meter on the pipeline, and

keep the smart meter horizontally. Note: the smart water meter and joint should

not be bent forcedly.

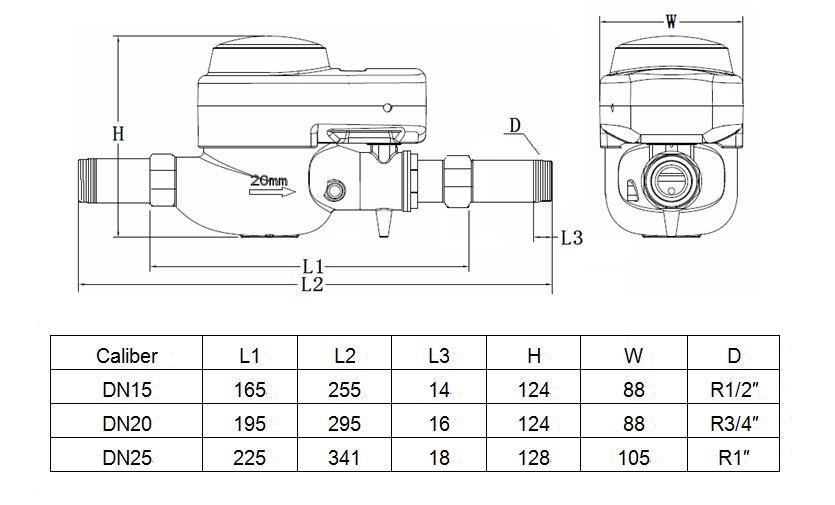

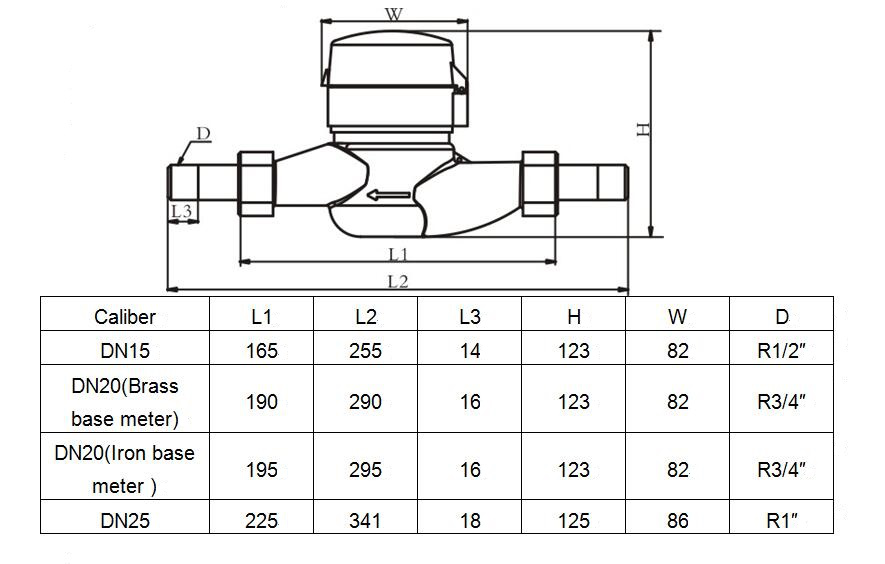

DIMENSION

MAIN TECHNIQUES

1. Photoelectric sensor and electronic circuit

are sealed in the seal box of counter, so it is waterproof, moisture-proof and

anti-attack, and photoelectric sensor adopts unique circuit design and

fabrication process, so it

completely solves optical interference problem, therefore, in any light

condition (including direct sunlight) and dark environment, it will not affect the correct reading of data, and it also greatly improve the safety of meter reading.

2. Adopt no power and photoelectric direct reading technique, the reading is always the present reading of water meter, so no matter the dial wheel rotates in forward or reverse direction, or the shaking of pipe, it will not influence the reading result, and it will also not be affected by magnetic interference, thus it is safe and reliable.

3.Simple wiring way, no requirement of topological structure, any wiring way, such as star type and cross-over type are allowed.

4. Adopt absolute coding method. There is a unique code corresponding to each number on the dial wheel, and is fixed on the meter head, when the system work, no need to initialize, after installation, then it can be used.

5. Only when the measurement meter reading data, the meter reading device will supply power, and the working time is very short, usually, the measurement meter doesn’t need power supply, so it can greatly improve the service life of meters, and don’t need professional maintainer, and it will not lose data because of power failure and network failure.

6. Adopt advanced encoding and decoding technique, which guarantee the data accuracy is 100% when in carry critical state.

7. Each meter has a unique ID No., and has complete production, debugging, usage and maintenance record.

8. Anti-interference and anti-attack of strong magnetic field and optoelectronics.

9. No need of power supply for daily work.

10. With remote valve control function that can stop water supply remotely.

PRODUCTS

PRODUCTS