HOW TO USE

1. Remote meter reading

The smart gas meter transmits meter data by wireless meter reading network, the management staff can inquiry gas consumption, valve status, and battery status etc, they can also read meter remotely by wireless meter reading software or hand held unit.

2. Close valve remotely

The gas meter will close valve and stop gas supply after get the command of close valve from the wireless software or hand held unit.

3. Allow to open valve remotely

Transmit command of open valve to the gas meter by wireless software or hand held unit, the gas meter will enter into allow to open valve status after get the command, while not directly open valve.

4. Open valve

When the gas meter in the status of allowing to open valve, press the button on the meter shell, the gas meter will open valve to supply gas (note: press the button cannot open gas meter valve to supply gas if the meter is in the status of forbidden to open valve)

5.

Close valve when attacked

When

the gas meter is attacked by strong electricity and magnet, the meter will

close valve automatically. The attack source should be removed firstly, and

then press the button to open valve and recover gas supply.

6.

Replace battery

The battery need to

be replaced when the gas meter stops gas supply automatically, the

batteries are 3 pieces of AAA alkaline dry battery. When replace battery, open

the battery cover, replace the old battery with new one, and then press the

button on the meter shell to recover gas supply.

FUNCTIONS

1. Micropower technology: the power consumption is less than 10μA at ordinary times, adopt timing detect technique to improve the battery life.

2. Electrical valve technique: adopt electrical valve technique, work reliably and lower loss of pressure.

3. Totally sealed design: all the circuits are sealed by high performance casting glue, so there is no exposed electrode, good leak tightness.

4. Anti-attack of strong electricity or magnet: gas meter will close valve automatically and give indication when being attacked by strong electricity or magnet.

5. Wireless transmission technique: no need of communication cable layout, greatly reduce the installation cost.

6. Micro-computer and microstorage technique: high integrated and high reliability.

TECHINICAL PARAMETERS

|

Item

|

Smart Gas Meter

|

|

Model

|

G6

|

G10

|

G16

|

G25

|

G40

|

G65

|

|

Permanent Flowrate

qn (m³/h)

|

6

|

10

|

16

|

25

|

40

|

65

|

|

Maximum Flowrate

qmax m³/h

|

10

|

16

|

25

|

40

|

65

|

100

|

|

Minimum Flowrate

qmin m³/h

|

0.06

|

0.10

|

0.16

|

0.25

|

0.40

|

0.65

|

|

Transitional Flowrate qt m3/h

|

1.0

|

1.6

|

2.5

|

4.0

|

6.5

|

10.0

|

|

Initiate Flowrate dm³

|

≤5

|

≤8

|

≤8

|

≤13

|

≤20

|

≤32

|

|

Cyclic Volume of

Gas Volume Meter (1) dm³

|

3.5

|

10

|

10

|

20

|

30

|

55

|

|

Weight(kg)

|

5

|

10

|

10

|

18

|

27

|

35

|

|

Total Pressure

Loss

|

≤250Pa

|

≤375Pa

|

≤500Pa

|

|

Minimum Reading

|

0.002m³

|

|

Maximum Reading

|

999999.99m³

|

|

Leak

Tightness

|

No leak when≤45kPa

|

|

Working

Pressure

|

0.5kPa~30kPa

|

|

Basic Error

|

qmin≤q<qt ≤±3%; qt≤q≤qmax ≤±1.5%

|

|

Measurement Accuracy

|

Class 1.5

|

|

Working

Temperature

|

-10℃~40℃

|

|

Security

of IC Card

|

one

card for one meter, cannot be copied

|

|

Life of

IC Card

|

Use

time≥100,000 times

|

|

Alarming

Way

|

Close

valve

|

|

Alarming

Volume

|

The

alarming volume will be 1/16 m³ of the

current purchased volume (count the Integer) or 20m³,

50m³ ( Purchasing volume for one time>255 m³, the alarming volume will be 50 m³)

|

|

Static Working

Current

|

≤20.0μA

|

|

Working Power Supply

|

AA

alkaline dry battery (4 pieces of 1.5V)

|

INSTALLATION

1. The

installation shall be done by the professional person of Gas Power Company, and

shall be installed according to the requirement of code for management of city

gas engineering

2. The gas

meters are forbidden to be installed in the bedroom, bathroom and the place

where there are flammable, explosive and dangerous goods.

3. The gas

meter shall be installed in the good aeration place, and shall be convenient

for reading, observe and overhaul.

4.

The gas meter shall be installed vertically, and cannot slant, and the vertical

missing should be less than 1mm, the horizontal distance between the gas meter

and the gas stove shall not less than 300mm

5.

Power socket and wire can not be installed near the gas line, and the distance between

the power socket and the gas meter shall not be less than 300mm. No power wire

and electrical equipment can be installed 500mm within the gas meter.

6.

Pay attention to the direction of gas meter inlet and outlet, and choose the

right gas meter, as it cannot be installed reversely.

7.

Screw thread is forbidden to be filled with any sealing objects.

8.

After finish the installation, should test the leak tightness. And if it is qualified,

then it can be used. Before inflaming, should discharge all of the air inside

the gas meter and pipeline.

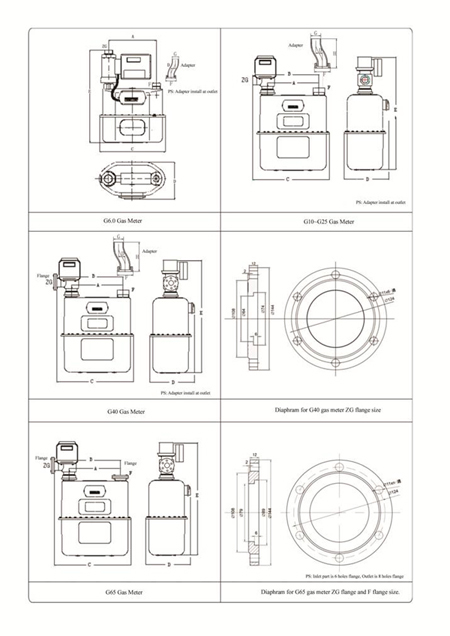

DIMENSION

MAIN TECHNIQUES

1. Micropower technology: the power consumption is less than 10μA at ordinary times, adopt timing detect technique to improve the battery life.

2. Electrical valve technique: adopt electrical valve technique, work reliably and lower loss of pressure.

3. Totally sealed design: all the circuits are sealed by high performance casting glue, so there is no exposed electrode, good leak tightness.

4. Anti-attack of strong electricity or magnet: gas meter will close valve automatically and give indication when being attacked by strong electricity or magnet.

5. Wireless transmission technique: no need of communication cable layout, greatly reduce the installation cost.

6. Micro-computer and microstorage technique: high integrated and high reliability.

PRODUCTS

PRODUCTS